AC DRIVES

Drive Brushless DF1 Falcon

Overview

Variable Supply: from 230Vac to 400Vac single phase or three phases.

Rated Currents from 3A till 42A.

Realized with a superficial mounting technology and completely digital, DF1 FALCON is an universal drive of last generation especially suitable for Closed Loop control of Brushless & Vectorial motors. Totally configurable by an easy and intuitive user interface DF1 offers solutions to the most range of applications in the Motion Contol market. DF1 represents nowadays one of the most news on the market thanks to the technologies used to realize the product. The Speed Control, Current and Position are entrusted to a last generation DSP which is extremely fast and it guarantees the parameters processing in real time. Mechanical compactness, exceptional reliability and a very good ratio between quality and price complete the product which can be considered one of the market datum point.

A RS232 serial lets to connect a PC to DF1 and, through the communication software which is issued with the drive, visualize in real time the most important sizes as motor current, motor speed, etc. The Field bus represents nowadays an undiscussable facilitation for the automatic machines manufacturers, allowing to save in a significant way the whole part of panel and wiring. DF1 has been thought and realized for these type of users, for this reason it has been chosen a field bus entirely free and open as the CAN Open with functions of positioner interpolating, electric axis and electronic cam which let to simplify the CNC, PLC working.

Discover More

Variable Supply: from 230Vac to 400Vac single phase or three phases.

Rated Currents from 3A till 42A.

Realized with a superficial mounting technology and completely digital, DF1 FALCON is an universal drive of last generation especially suitable for Closed Loop control of Brushless & Vectorial motors. Totally configurable by an easy and intuitive user interface DF1 offers solutions to the most range of applications in the Motion Contol market. DF1 represents nowadays one of the most news on the market thanks to the technologies used to realize the product. The Speed Control, Current and Position are entrusted to a last generation DSP which is extremely fast and it guarantees the parameters processing in real time. Mechanical compactness, exceptional reliability and a very good ratio between quality and price complete the product which can be considered one of the market datum point.

A RS232 serial lets to connect a PC to DF1 and, through the communication software which is issued with the drive, visualize in real time the most important sizes as motor current, motor speed, etc. The Field bus represents nowadays an undiscussable facilitation for the automatic machines manufacturers, allowing to save in a significant way the whole part of panel and wiring. DF1 has been thought and realized for these type of users, for this reason it has been chosen a field bus entirely free and open as the CAN Open with functions of positioner interpolating, electric axis and electronic cam which let to simplify the CNC, PLC working.

Discover More

AC BRUSHLESS DRIVE AZ3 SERIE

Overview

AZ3 is an extra-low voltage drive designed for the control of AC/DC brushless motors and DC motors. The high versatility of this product is demonstrated by the various position feedbacks available (Hall, incremental encoders), the different kind of inputs (analog, digital and frequency) and outputs (digital, power PWM) and the communication interfaces (CAN, Modbus); furthermore it is available in both integrated and stand-alone versions. The drive can also operate with a secondary encoder input for direct axis control and can manage an electromechanical brake or a braking resistor without relay/contactor. The long list of the available functions is completed with the emulated encoder outputs and the high-frequency inputs.

- 24V DC to 60V DC power supply

- 30A nominal, 60A di picco (5s)

- CANopen DS402, Modbus RTU (over RS485)

- Windows® based software interface

- Digital and analog inputs

- Power PWM outputs (brake/resistor)

Discover More

AZ3 is an extra-low voltage drive designed for the control of AC/DC brushless motors and DC motors. The high versatility of this product is demonstrated by the various position feedbacks available (Hall, incremental encoders), the different kind of inputs (analog, digital and frequency) and outputs (digital, power PWM) and the communication interfaces (CAN, Modbus); furthermore it is available in both integrated and stand-alone versions. The drive can also operate with a secondary encoder input for direct axis control and can manage an electromechanical brake or a braking resistor without relay/contactor. The long list of the available functions is completed with the emulated encoder outputs and the high-frequency inputs.

- 24V DC to 60V DC power supply

- 30A nominal, 60A di picco (5s)

- CANopen DS402, Modbus RTU (over RS485)

- Windows® based software interface

- Digital and analog inputs

- Power PWM outputs (brake/resistor)

Discover More

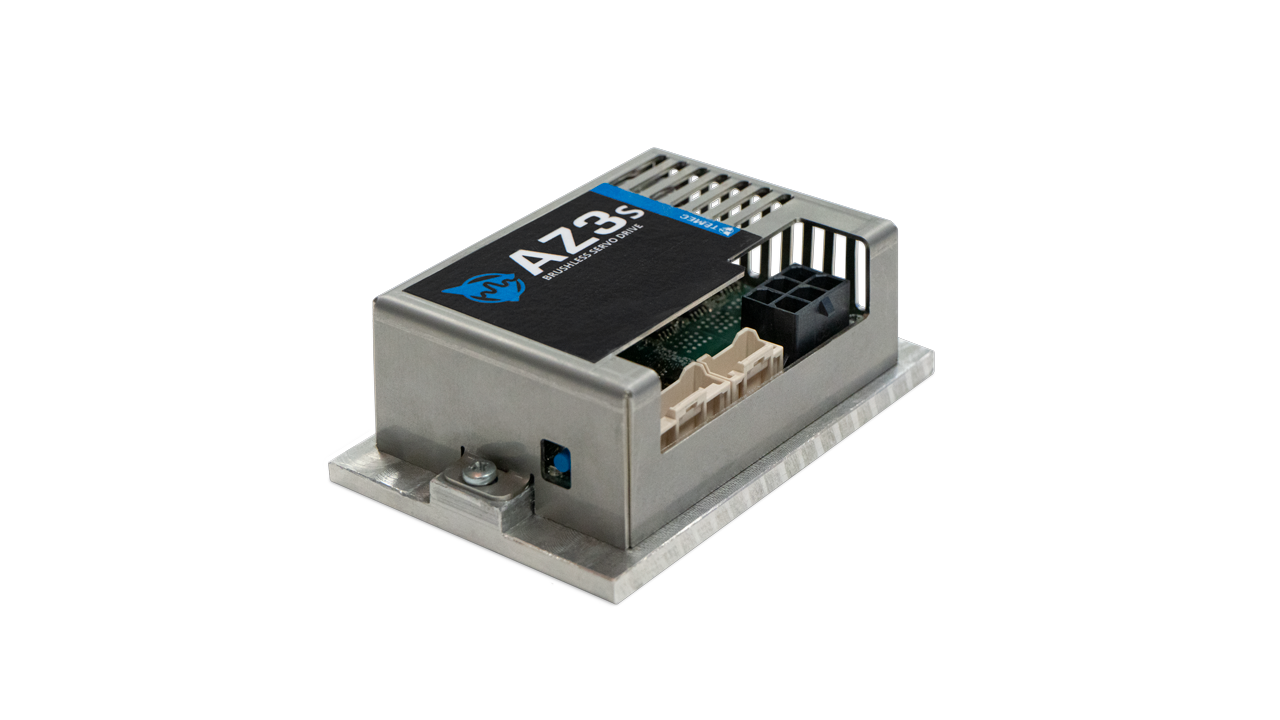

AC BRUSHLESS DRIVE AZ3s SERIE

Overview

Supply voltage: 24 V to 48 V DC (20 V to 55 V absolute maximum rating).

Output continuous current : 17 A**, 34 A peak (2s)**.

Maximum output power: 800 W**.

Motor type: Brushless AC, Brushless DC, DC motor.

Operating temperature: -25°C ~ 60°C

Position feedbacks: Incremental encoder, Hall switches (120°), absolute encoder (BiSS, SSI, EnDat)*, predisposition for sensorless control*.

Inputs and outputs: 9 configurable input/outputs:

• Up to 4 analog inputs (Sin/Cos encoder*, potentiometer, PLC analog signals, etc.).

• Up to 9 digital inputs (open, close and stop button, limit switches, etc.).

• 2 high frequency digital inputs (pulse and direction control*, possibility to read a second encoder*).

• Up to 9 digital outputs (emulated encoder, fault signaling, etc.).

Power outputs: braking resistor, electromechanical brake.

Communications protocol: CAN / CANopen DS402, Modbus RTU (over RS485), UART.

Other features: Input for motor thermistor (NTC), power supply separable from logic power supply to be able to push the power supply beyond 55 V (limits to be defined).

Dimensions (width, length, height): PCB board (55 mm, 80 mm, 23 mm), heatsink with box (65 mm, 100 mm, 36 mm).

With these dimensions, it is easy to integrate the drive with linear actuators or small motors.

Firmware features: torque control, speed control, position control*, diagnostics, etc.

*Under firmware development.

**@ 25°C

Discover More

Supply voltage: 24 V to 48 V DC (20 V to 55 V absolute maximum rating).

Output continuous current : 17 A**, 34 A peak (2s)**.

Maximum output power: 800 W**.

Motor type: Brushless AC, Brushless DC, DC motor.

Operating temperature: -25°C ~ 60°C

Position feedbacks: Incremental encoder, Hall switches (120°), absolute encoder (BiSS, SSI, EnDat)*, predisposition for sensorless control*.

Inputs and outputs: 9 configurable input/outputs:

• Up to 4 analog inputs (Sin/Cos encoder*, potentiometer, PLC analog signals, etc.).

• Up to 9 digital inputs (open, close and stop button, limit switches, etc.).

• 2 high frequency digital inputs (pulse and direction control*, possibility to read a second encoder*).

• Up to 9 digital outputs (emulated encoder, fault signaling, etc.).

Power outputs: braking resistor, electromechanical brake.

Communications protocol: CAN / CANopen DS402, Modbus RTU (over RS485), UART.

Other features: Input for motor thermistor (NTC), power supply separable from logic power supply to be able to push the power supply beyond 55 V (limits to be defined).

Dimensions (width, length, height): PCB board (55 mm, 80 mm, 23 mm), heatsink with box (65 mm, 100 mm, 36 mm).

With these dimensions, it is easy to integrate the drive with linear actuators or small motors.

Firmware features: torque control, speed control, position control*, diagnostics, etc.

*Under firmware development.

**@ 25°C

Discover More

DC DRIVES

DC MOTOR DRIVER BOARDS AM - AMX - AMR SERIES

Overview

AM - AMX - AMR drives are characterised by compact dimensions and high performances due to the mos-fet working at 12kz pwm; there are particularly adapted for automation sector, they can drive both permanent magnets and separately excited type motors. Thanks to the wide range of voltages available both in AC and in DC, to the rated current and to the possibility to insert options, AM drivers are versatile in every market. The simplicity of use and the great reliability joint to the optimal quality/price ratio make the AM drivers series an important partner for small motion sector.

Discover More

AM - AMX - AMR drives are characterised by compact dimensions and high performances due to the mos-fet working at 12kz pwm; there are particularly adapted for automation sector, they can drive both permanent magnets and separately excited type motors. Thanks to the wide range of voltages available both in AC and in DC, to the rated current and to the possibility to insert options, AM drivers are versatile in every market. The simplicity of use and the great reliability joint to the optimal quality/price ratio make the AM drivers series an important partner for small motion sector.

Discover More

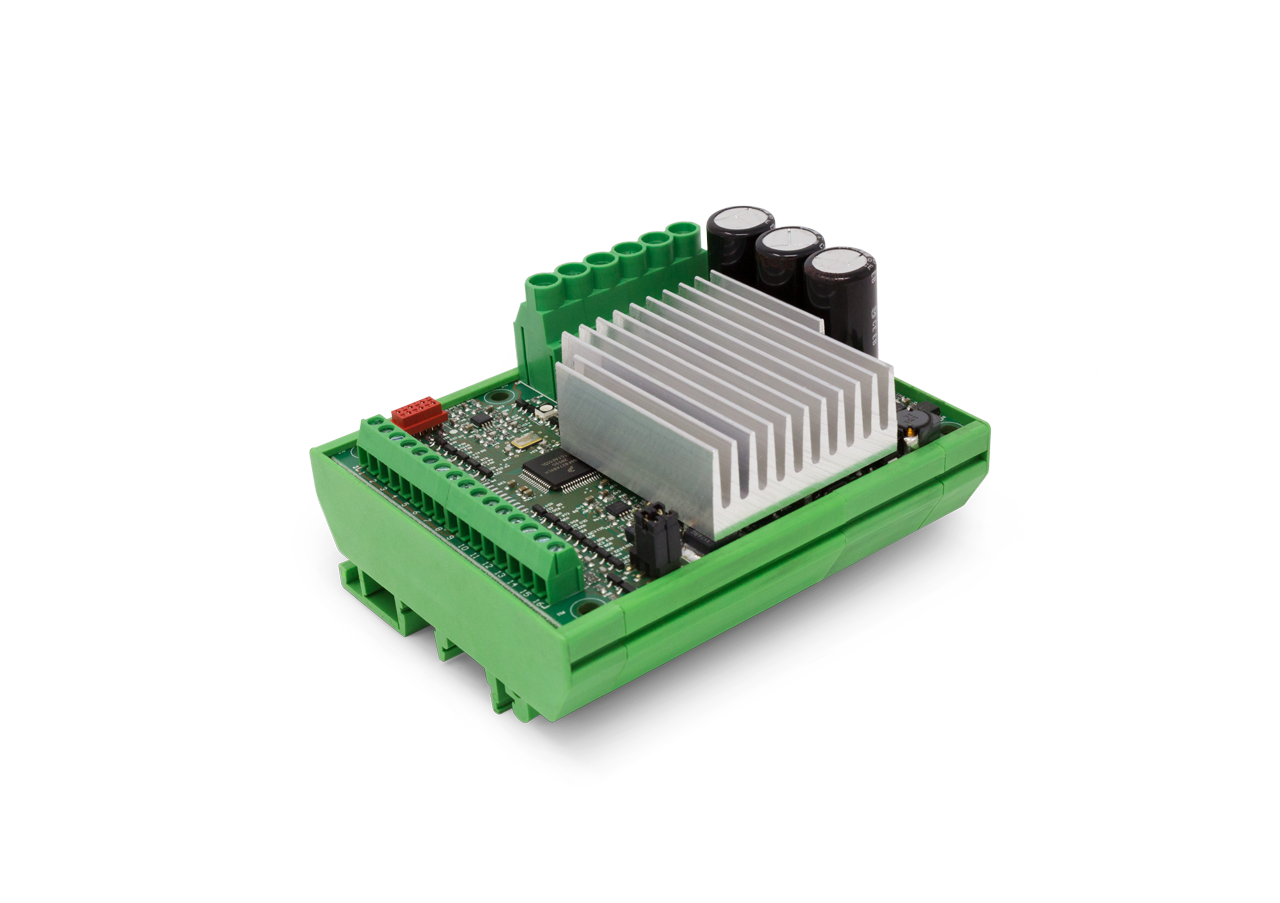

DC DRIVE AZ2 SERIE

Technical Data

- control of one/two linear actuators, independent or synchronized

- 12V DC to 48V DC power supply

- 10A or 15A, S3 – 30% – 5 minutes

- 12 digital inputs, 2 outputs

- incremental encoders

Applications

The AZ2 drive is designed for the control of linear actuators driven by DC motors especially when a synchronized movement of two actuators is required. AZ2 use can be extended to any application involving the control of DC motors.

Overview

AZ2 is a full electronic motor drive designed for the control of two DC motors in extra-low voltage applications. The power stage is based on MOS transistor technology, controlled by a pulse width modulation (PWM). A microcontroller elaborates the control data, generates the output waveforms and manages the communication interfaces. The user can exchange data and commands using the digital I/O and a Modbus interface; the last one is used for communication with the PC software through which the user can change parameters, monitor the status of the drive and read diagnostic information.

Discover More

- control of one/two linear actuators, independent or synchronized

- 12V DC to 48V DC power supply

- 10A or 15A, S3 – 30% – 5 minutes

- 12 digital inputs, 2 outputs

- incremental encoders

Applications

The AZ2 drive is designed for the control of linear actuators driven by DC motors especially when a synchronized movement of two actuators is required. AZ2 use can be extended to any application involving the control of DC motors.

Overview

AZ2 is a full electronic motor drive designed for the control of two DC motors in extra-low voltage applications. The power stage is based on MOS transistor technology, controlled by a pulse width modulation (PWM). A microcontroller elaborates the control data, generates the output waveforms and manages the communication interfaces. The user can exchange data and commands using the digital I/O and a Modbus interface; the last one is used for communication with the PC software through which the user can change parameters, monitor the status of the drive and read diagnostic information.

Discover More